Talk with our teams for your applications

Our prep station can meet the needs for repairing all kinds of vehicle bodies. In addition, we offer a scientific and reasonable customization service to any enterprise.

This product is primarily designed to get rid of dust, exhaust gas, or paint mist during such processes as polishing, welding, restoring, pretreatment before coating, as well as the local spraying. It can not only improve both working efficiency and product quality, but also assure customers of a clean working environment. Moreover, our product can secure the physical and psychological health of all production staff.

-

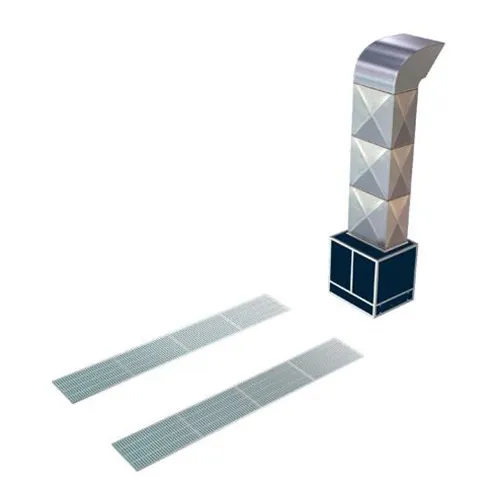

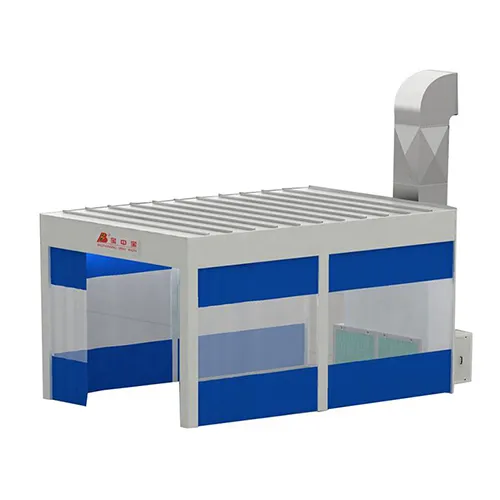

- 700A Prep Station This 700A prep station can be applied in all sorts of car repair and maintenance industry. It features low investment, simple installation, and small footprint. When a fan runs, the circulation of air allows the working environment to be pretty clean.

-

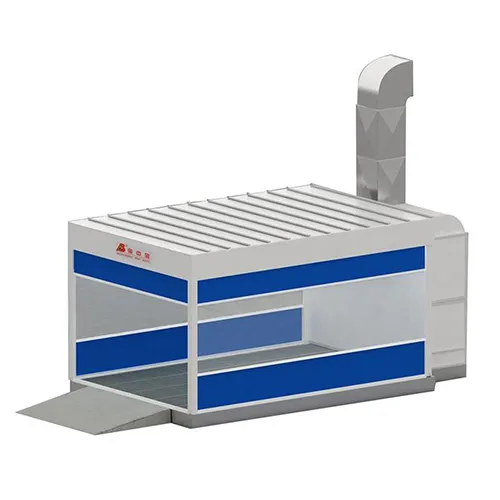

- 800A Prep Station This 800A prep station is characterized by low investment, easy installation, and very small area occupied. It can be found in all kinds of vehicle repair and maintenance industry.

-

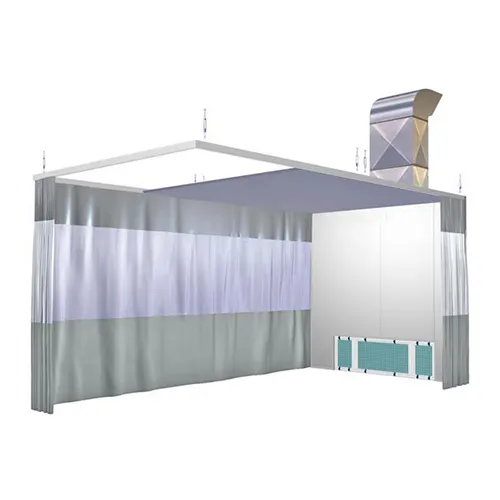

- 6100 Prep Station This 6100 prep station is ideal for diversified types of car repair and maintenance industry. It gives small footprint, simple installation, and low investment. The fully enclosed workspace creates a good workshop environment.

-

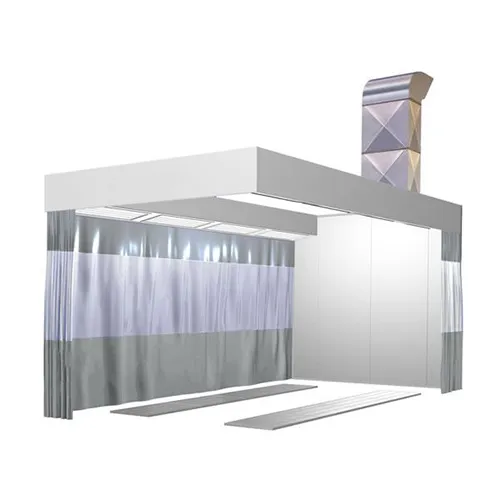

- 6200 Prep Station Centrifugal Fan: The YDW series double-inlet centrifugal fan introduces the Siemens technology. It adopts the compression molded galvanized plates, which features large air capacity, low noise, and high temperature resistance. Detailed information is listed as follows.

-

- 6300 Prep Station Ceiling: At the top of our 6300 prep station, the plenum chamber adopts the cold-rolled steel plate which has gone through such processes as bending, spraying, and molding. The roof panel utilizes the galvanized steel plate, which is hoisted in use of steel rope.

-

- 6400 Prep Station This system adopts the Italian made exceptional-quality filter screen. The filter has multiple layers. It is placed at the bottom of the plenum chamber, and supported by the roof mesh.

-

- 6500 Prep Station The high-quality filter screen is made in Italy. This multi-layered structure is fixed at the bottom of the plenum chamber. It is supported by roof mesh.

-

- 6600 Prep Station The YDW series double-inlet centrifugal fan is formed of compression molded galvanized plates by adoption of Siemens technology. Made by a fan specialist, it features great air capacity, low noise, and superior temperature resistance.

-

- Multifunction Prep Station This production line makes use of the spraying or curing structure that can work independently. All side walls of the surface paint spray booth and paint curing booth are composed of removable doors.

Merits

- Our company takes the lead in adopting a progressive design concept from overseas countries among enterprises belonging to the same industry.

- We put to use a top-ranking domestic design team that is good at providing personalized solutions.

- Our product is designed, manufactured and assembled under strict and precise quality control.

Reliable Paint Booth and Finishing System Provider

Contact Us

Recent Projects

-

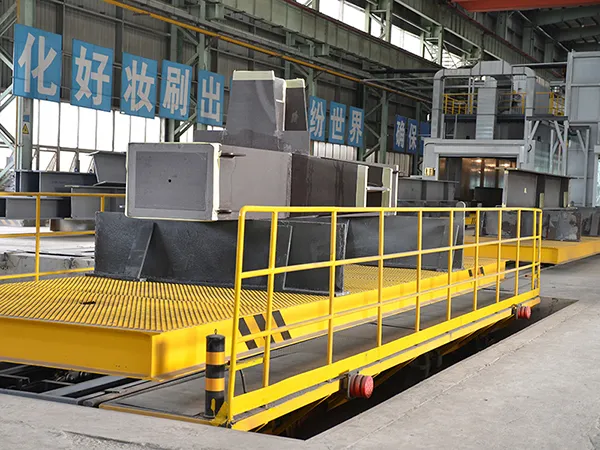

- Bulldozer Painting Line in Tianjing Yishan Company Firstly, we are required to accomplish the task of painting 6,000 bulldozers each year.

-

- Automotive Spray Booth in Canada Customers are pretty satisfied with our manufactured goods.

-

- Large Size Bus Spray Booth in Peru Our company has undertaken to build a large-sized spray booth for the customers from Peru.

Paint Booth & Finishing System for Your Applications